Tire Manufacturing

Everyone knows what a tire is and what it’s for, right? It’s a black donut made of rubber, placed on a vehicle so the driver can transport himself and his cargo from point A to point B. The tire has to allow for easy steering, braking, and cornering. It must provide for a comfortable, safe ride. It needs to be durable. And that’s about the extent of what most of us know.

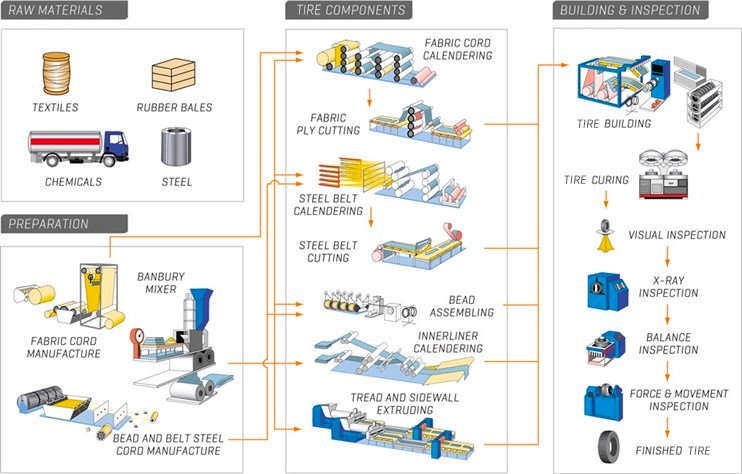

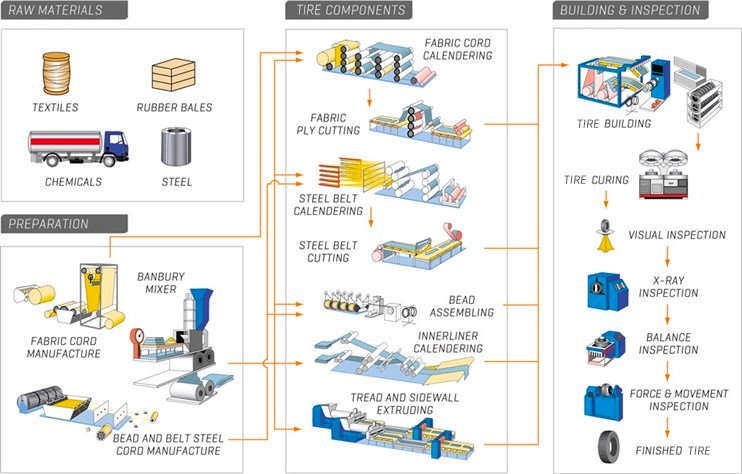

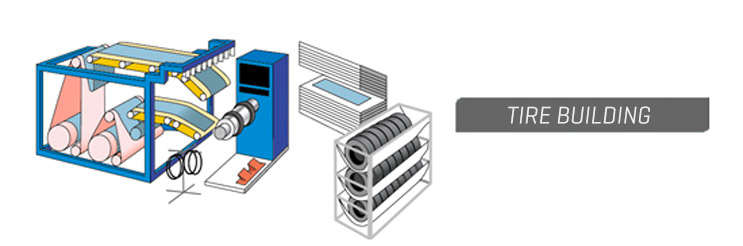

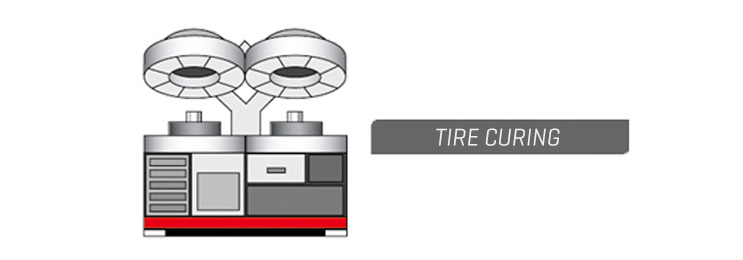

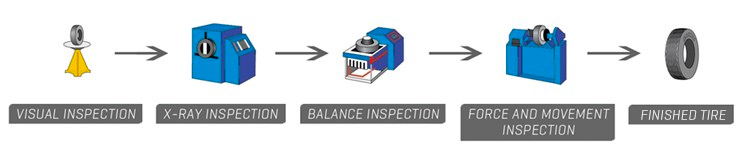

Use the tabs above to look at the different stages of the manufacturing process.

SHOWING YOU WHAT WE’RE MADE OF