Tyre Pressure

Why is tyre pressure important?

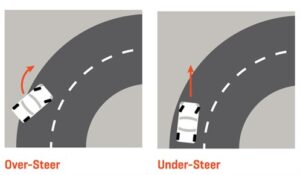

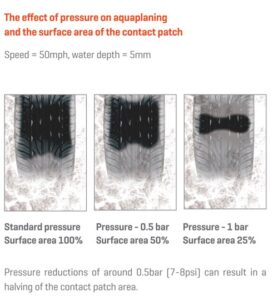

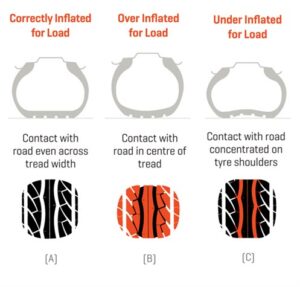

Tyres should be kept at the pressure recommended by the vehicle manufacturer at all times. Incorrect pressures can affect a vehicle’s handling, cause premature tyre wear and damage a tyre irreversibly.

Motorists are encouraged to check tyre pressures regularly, at least once a month, and before every long journey, including the spare tyre where applicable.

Tyre pressures should also be checked when the tyres are cold and before the vehicle travels long distances. As they warm, tyres increase in pressure which is a normal part of driving.