With Multiple Victories, Maxxis Is King at Crandon

Triumph followed triumph for Maxxis at the Championship Off-Road Polaris World Championships.

Read More

Keegan Swenson Wins XC Marathon World Championship

Swenson victorious after 77 miles and 17,000 feet of elevation

Read More

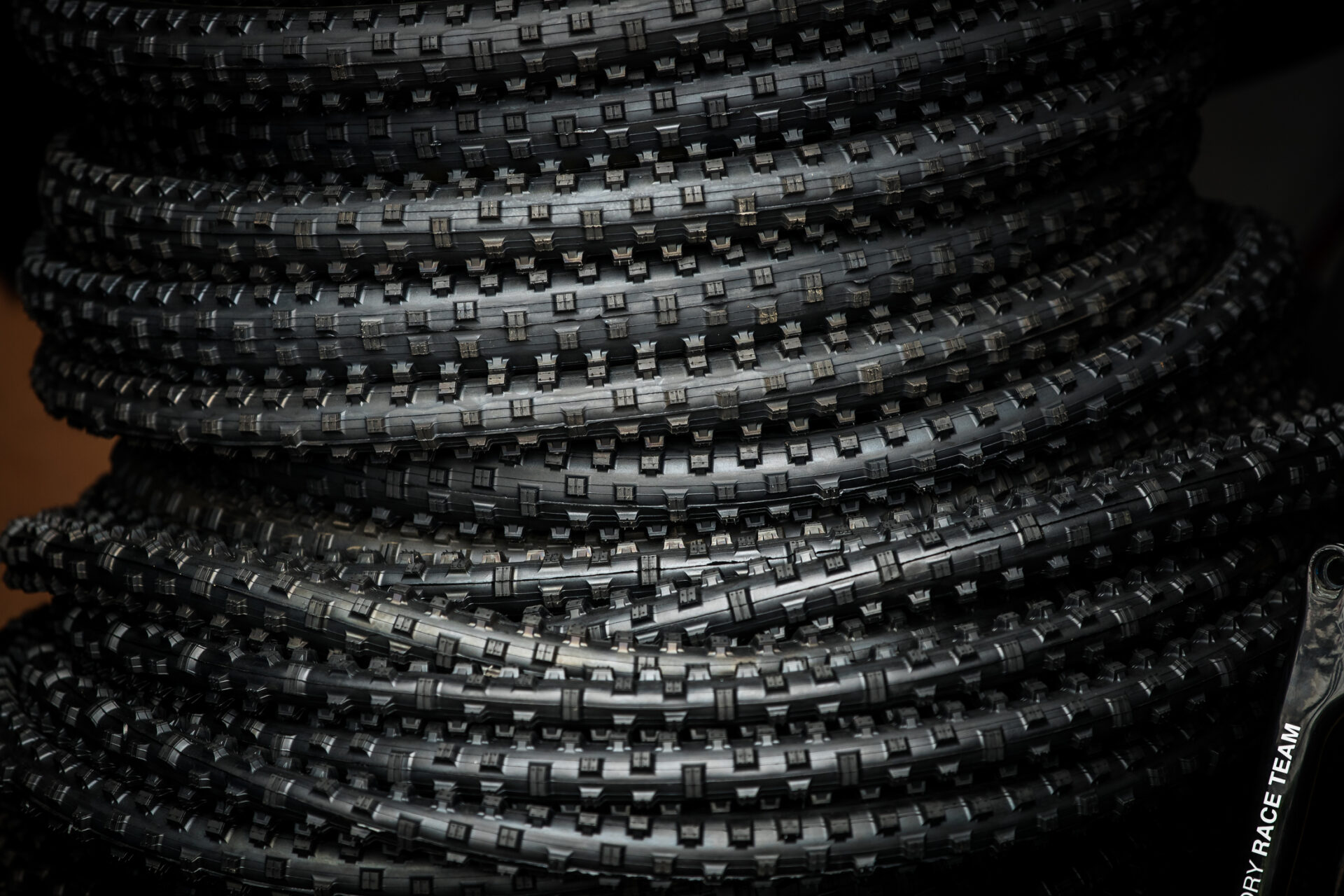

The Maxxis Dissector is back, and it’s better than ever.

Read More

Dealer Locator